Understanding the Difference

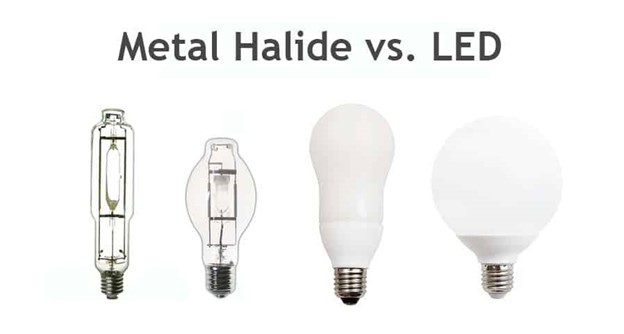

Before we compare metal halides and LEDs, it is important to understand what makes them different. Metal halides work similarly to incandescent light bulbs. Encased in a thick glass, metal halides operate when an electrical current passes through a combination of metal and halogen elements, generating gas that creates visible light. Metal halides have long been the go-to lighting for areas that require high-intensity lighting, such as parking lots, pedestrian walkways, athletic facilities, and fields. LEDs, short for Light Emitting Diodes, do not create a gas in order to work. LEDs, instead, use solid-state technology. Each shatter-resistant plastic lamp includes a built-in diode. This diode, which includes both a cathode and anode, creates a visible light when an electrical current is provided.

Interested in learning more about the different Lighting Applications to utilize metal halides and LEDs? We have a whole education section dedicated to Lighting Applications and Products.

Lumen Efficiency

Both metal halides and LEDs are considered to be more energy-efficient than incandescent lamps. However, when it comes down to the numbers, the energy efficiency of an LED far exceeds that of a metal halide lamp. A new 400-watt metal halide lamp is rated to last up to 20,000 hours. Selling points for this lamp also include a color temperature of 4000K and initial lumens at 32,000 to 36,000. This means that the initial light output is extremely high. However, metal halide bulbs tend to lose those lumens very quickly. In fact, it is not uncommon to see lumens depreciate by 20% within the first six months of use. In other words, that super bright metal halide will only produce 28,800 lumens after just six months of use. (Once used for 10,000 hours, a metal halide typically produces half of the initial lumens!) In addition to this, metal halide lamps are considered to be omnidirectional; this means that they produce lights in every direction. To prevent wasted illumination, reflectors are often used in combination with metal halide lamps to force light into a single direction instead of all over. When a reflector is added, metal halide lamps lose an additional 30% of their lumens. This means that after 6 months, your lumens are actually closer to 20,000 instead of 36,000. By comparison, LED lights are directional. They do not waste lumens by spreading light everywhere, which helps to conserve brightness. However, even more to the point, LEDs retain at least 70% of their initial lumens throughout the duration of their lifespan. At approximately 100,000 hours, that means an LED not only stays brighter longer, it also lasts three to five times as long as a metal halide version.

For more on an LED’s lumen efficiency, read our blog Understanding Luminous Efficacy!

LED vs. Metal Halide Cost Savings

We understand that, for a business, what it comes down to is cost savings. So let’s take a look at two of the most important cost factors: energy and maintenance expenses.

Energy

Because an LED is more energy-efficient than a metal halide, it stands to reason that these lamps save you more money too. It is a fact that metal halides are more efficient than incandescent bulbs. So, there is a cost savings there. However, LED lights go beyond that. We provided the example of a 400-watt metal halide above. However, at just 150 watts, an LED can burn even brighter! This means they consume less energy to produce the same, if not better, lighting than that of a metal halide. This means your power bill is reduced significantly through simply swapping metal halides with LEDs. It is an immediate cost savings that cannot be ignored.

Maintenance

Lighting maintenance is often overlooked when it comes to calculating your cost savings. Metal halides do not last nearly as long as LEDs. In fact, after a review of the facts above, it should be apparent that the lifespan of a metal halide depreciates rapidly. However, even if a metal halide lasted the full 36,000 hours, LEDs would still far exceed that. With between 100,000 and 150,000 hours of use, LEDs have a substantially longer lifespan. This means you will need to replace them less often than you would have to replace a metal halide.

Metal Halide vs. LED Quality

Let’s not forget the other important part of selecting the right lighting for your business: the quality of the light being produced. After all, it is important to find a lighting source that protects your equipment, employees, and everything else your business may need.

Performance

We cannot stress enough how quickly metal halides depreciate. But there are other factors to consider. For larger metal halides, such as those that illuminate fulfillment centers or heavy machinery lots, it can take up to 30 minutes to warm up and reach maximum illumination. Even smaller metal halides can take up to five minutes to reach full illumination. LEDs, however, read maximum illumination immediately. That means even more cost savings. Why? Because your metal halides have to be turned on well before your workday begins to reach full illumination.

Lumens

Both metal halide lamps and LED bulbs can produce high lumens. The main difference here is the depreciation rate. As we pointed out several times, metal halides depreciate very quickly. In fact, after six months you will already need to start looking into replacing them. However, LEDs can last years at the same lumen levels. At worst, they may have a 30% depreciation over the course of 100,000 hours, which is still significantly better than the lumen lifespan of a metal halide.

LEDs with Action Services Group

If you have been using metal halides, it may be time to switch to LEDs. Based on the cost savings, efficiency and quality – LEDs are superior light sources for almost every business. If you are considering making the switch to LEDs, contact Action Services Group at 610-558-9773, email [email protected] or schedule a call.

Hello There. I found your blog using msn. This is a

really well written article. I will make sure to bookmark it and return to read more of your

useful information. Thanks for the post. I will certainly comeback.