Preventive maintenance can make or break an entire electrical system. Businesses could face costly repairs, extensive downtime, and safety accidents should the electrical system fail. However, preventative electrical maintenance can stop those instances from occurring by addressing the issues before more serious problems arise.

Why Preventive Electrical Maintenance Is Essential

Industrial facilities are complex ecosystems that rely on reliable power to operate efficiently. Preventive electrical maintenance ensures these systems remain safe, dependable, and energy efficient. The following benefits highlight why it should be a priority for every facility manager.

Reducing Unexpected Equipment Failures

Industrial facilities have complex systems that rely on lots of machinery to get the job done. Should one piece malfunction, it can disrupt the entire operation, leading to downtime. Yet, electrical equipment such as switchgear, transformers, wiring, and circuit breakers deteriorates over time. Preventive maintenance has the power to stop unexpected electrical issues from happening through regular inspections, testing, and repairing issues before they become bigger problems.

Enhancing Safety and Preventing Hazards

Many industrial facilities rely on heavy machinery and have high-voltage areas. Malfunctioning equipment and electrical hazards, such as shocks, fires, and arc flashes, pose a serious risk to employees. By scheduling preventative maintenance checks, business owners can ensure their employees are safe while maintaining compliance with OSHA and NFPA.

Extending Equipment Lifespan

Running equipment in poor electrical conditions, such as with loose connections, voltage fluctuations, or overheating, shortens its life. Preventive electrical maintenance reduces strain on critical systems, allowing them to operate within safe parameters. Over time, this extends the usable life of equipment, postpones expensive replacements, and maximizes capital investment.

Industrial businesses like factories, manufacturing, and warehouses have higher energy consumption than other industries. Having electrical systems that aren’t up to par drives energy consumption even higher. Issues like overloaded circuits, worn-out components, or dirty connections increase resistance, which are signs that the system needs to be repaired.

Ensuring Compliance with Electrical Standards

Industrial facilities are held to strict codes and standards, including NFPA 70B, NFPA 101, OSHA requirements, and local building codes. Preventive electrical maintenance ensures systems stay in compliance, minimizing the risk of penalties, lawsuits, or liability in the event of an accident.

Minimizing Business Disruptions

A single power failure can halt operations, stop production lines, and cause significant revenue loss. Preventive electrical maintenance supports business continuity by ensuring critical systems remain operational, even in demanding industrial environments.

Key Preventive Electrical Maintenance Measures

Preventive maintenance is more than a checklist, it’s a structured program of inspections, testing, upgrades, and staff training. The following practices form the foundation of effective industrial electrical maintenance:

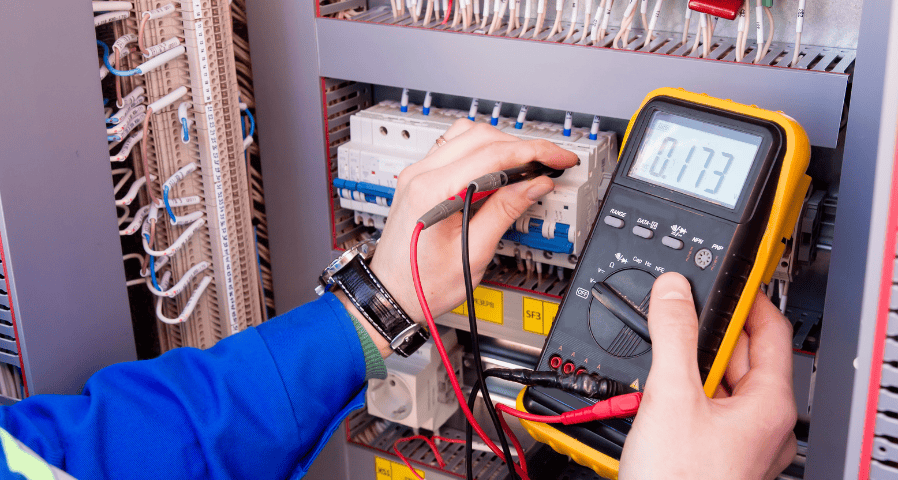

Regular Inspections: Routine inspections by qualified electricians should include a full review of panels, wiring, switchgear, outlets, and protective devices. Look for wear, corrosion, overheating, and other warning signs.

Thermal Imaging Scans: Infrared technology can identify overheating components long before they fail. Hot spots often indicate loose connections, overloaded circuits, or deteriorating insulation.

Circuit Breaker and Panel Testing: Circuit breakers must be tested to ensure they trip correctly when needed. Preventive programs should include routine functional testing of breakers, fuses, and protective relays.

Cleaning and Tightening Connections: Dust, debris, and loose connections are common culprits in electrical failures. Cleaning electrical panels, tightening connections, and lubricating moving parts help reduce risks.

Load Management: Preventive maintenance should include load analysis to ensure circuits are not overloaded. Balanced distribution reduces stress on systems and prevents failures caused by overcapacity.

Emergency Power System Maintenance: Generators and uninterruptible power supply (UPS) systems must be tested regularly to ensure reliability during outages. Preventive checks include fuel inspections and load simulations.

Electrical Upgrades: Replacing outdated lighting with LEDs, installing energy management systems, or adding smart sensors are examples of proactive upgrades that improve performance and safety.

Training Employees on Electrical Safety: All employees should be trained on electrical hazards, lockout/tagout procedures, and emergency protocols. Awareness reduces risks and helps identify issues early.

Maintenance Tracking Technology: Using computerized maintenance management systems (CMMS) ensures inspections, schedules, and tasks are completed on time, reducing the chance of overlooked issues.

Preventive electrical maintenance is essential for keeping industrial facilities safe, compliant, and operating at peak efficiency. By addressing issues before they escalate, you’ll reduce downtime, avoid costly repairs, and extend the life of your systems. Schedule a call with Action Services Group today to discuss a preventive maintenance plan for your facility.

Best Practices for Industrial Electrical Maintenance

To maximize the effectiveness of preventive electrical maintenance, facility managers should follow these best practices:

- Develop a structured electrical maintenance plan – Base it on equipment criticality, manufacturer recommendations, and compliance requirements.

- Schedule maintenance during planned downtime – This reduces disruption and ensures smooth operations.

- Work with qualified professionals – Only licensed electricians with industrial experience should perform inspections and repairs.

- Document every maintenance activity – Accurate records provide evidence of compliance and help track performance trends.

- Regularly review and update the plan – Adjust schedules as systems age, facility demands change, or new regulations are introduced.

Risks of Neglecting Preventive Electrical Maintenance

Failing to invest in preventive maintenance carries significant risks for industrial facilities.

Increased Downtime and Lost Revenue

Unexpected failures often lead to extended downtime. For manufacturers, this means production losses, missed deadlines, and unhappy customers.

Higher Repair and Replacement Costs

Neglect allows small issues to escalate into major equipment failures. Emergency repairs and premature replacements cost far more than preventive upkeep.

Safety Hazards and Liability

Electrical fires, shocks, and arc flashes are real dangers. Without proper maintenance, facilities increase the likelihood of accidents that put employees at risk and expose the business to lawsuits.

Energy Waste and Higher Operating Expenses

Inefficient systems waste energy and inflate utility bills. Over time, these added costs significantly impact profitability.

Compliance Violations

Regulatory fines, shutdown orders, and legal penalties can result from failing to meet electrical safety standards. Noncompliance also damages a company’s reputation with stakeholders and clients.

Conclusion

Industrial electrical maintenance should be viewed as a strategic investment in long-term operational success. By implementing regular inspections, testing, upgrades, and staff training, facility managers can safeguard both their people and their operations.

Action Services Group has a network of trained electrical technicians across the country to assist in preventative maintenance needs, like inspections, testing, and repairs. To learn more, call 610-558-9773, email [email protected], or schedule a consultation that fits your schedule.

0 Comments