Outsourcing Maintenance & Lighting Upgrades: How Property Managers & MUDs…

Outsourcing lighting upgrades and maintenance needs improves tenant retention and boosts ROI for property managers.

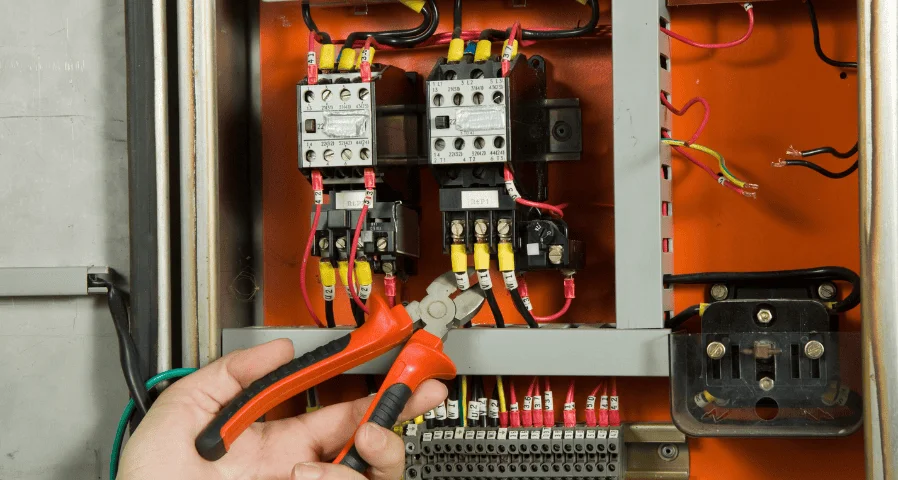

Every business relies on a dependable electrical system to keep operations running smoothly and ensure the safety of employees and occupants. Some electrical issues can look small at first, but could be a sign of underlying issues that could trigger downtime and costly repairs. Awareness of the most common electrical issues businesses face provides the knowledge you need to keep your organization running smoothly.

Loose or improperly tightened connections are one of the leading electrical downtime causes, responsible for nearly a third of all electrical failures. They typically arise from vibration, thermal cycling, or poor installation practices. Over time, loosened terminals and lugs increase resistance at connection points, causing heat buildup that can damage conductors, insulation, and even entire panels.

Avoidance strategy: Implement torque verification during installation, schedule infrared thermography inspections to detect hot spots, and retighten connections as part of your routine preventive electrical maintenance plan.

Insulation breakdown accounts for nearly 10% of common electrical failures. Aging materials, high temperatures, or mechanical abrasion can compromise insulation integrity, leading to short circuits or electrical shocks. Moisture ingress can accelerate this degradation.

Avoidance strategy: Conduct regular insulation resistance testing, replace aging cables proactively, and maintain dry, clean environments for electrical enclosures.

Inspections are critical to the early detection of any electrical issues. Skipping regular inspections or not performing them well leaves possible maintenance needs undetected until they cause larger problems. A single corroded terminal, uncalibrated breaker, or unbalanced load can silently degrade system reliability.

Avoidance strategy: Establish a documented inspection with a reliable electrical contractor and schedule based on equipment criticality or environmental factors. Utilize both visual checks and diagnostic tools like thermal cameras, current analyzers, and vibration sensors.

Improper documentation is an often-overlooked electrical maintenance mistake. Accurate maintenance logs, test data, and equipment history are key to helping identify recurring problems within an electrical system, resulting in repetitive breakdowns and inefficient troubleshooting.

Avoidance strategy: Standardize reporting formats for every inspection or repair. Maintain digital records that include dates, findings, parts replaced, and corrective actions. This builds an evidence-based maintenance culture that supports long-term reliability.

Preventive maintenance strategies are a must have for businesses looking to reduce electrical downtime and costly maintenance repairs. By getting ahead of problems before they escalate, you can improve the lifespan and health of your electrical system, create a safer work environment, and improve business operations.

Preventive strategies include:

These activities extend equipment lifespan, reduce unplanned outages, and lower long-term operating costs.

While preventive electrical maintenance focuses on scheduled activities, predictive maintenance uses real-time data to anticipate failures before they occur. Through smart technology, sensors can monitor and detect performance issues and signal them in the early stages. This gives facility managers reliable data to improve maintenance efforts.

Electrical maintenance mistakes like loose connections, faulty insulation, insufficient inspections, and poor documentation can silently erode reliability until downtime becomes inevitable. Implementing a preventive maintenance program to stay on top of scheduling, inspections, and routine maintenance lowers the risk of common mistakes and safeguards your electrical system.

Action Services Group has a network of electrical technicians across the country to assist in preventive maintenance needs, like inspections, testing, and repairs. To learn more, call 610-558-9773, email [email protected], or schedule a consultation that fits your schedule.