A 2026 Commercial Color Temperature Lighting Guide

Color temperature can be adjusted through AI powered lighting control technology. Doing so helps customize the…

Fluorescent tube lighting has illuminated warehouses, offices, schools, and retail spaces for more than a century. For decades, linear fluorescent lamps such as T12, T8, and T5 were considered the most efficient and practical solution for large, open environments. Today, however, LED tube technology has matured to the point where it outperforms fluorescent tubes in nearly every measurable category. Understanding how these two technologies compare helps facility managers and building owners make informed decisions about energy costs, maintenance, light quality, and long-term sustainability.

Linear fluorescent tubes are a form of gas-discharge lighting. Inside the glass tube is a small amount of mercury vapor and an inert gas. When electrical current passes through the tube, it excites the mercury atoms and produces ultraviolet radiation. This UV energy strikes a phosphor coating on the inside of the tube, causing it to fluoresce and emit visible light. A ballast is required to regulate the electrical current and start the lamp.

This technology was revolutionary when introduced, delivering far better efficiency and lifespan than incandescent lamps. However, it also brings inherent limitations, including reliance on mercury, sensitivity to temperature, ballast failures, and gradual lumen depreciation over time.

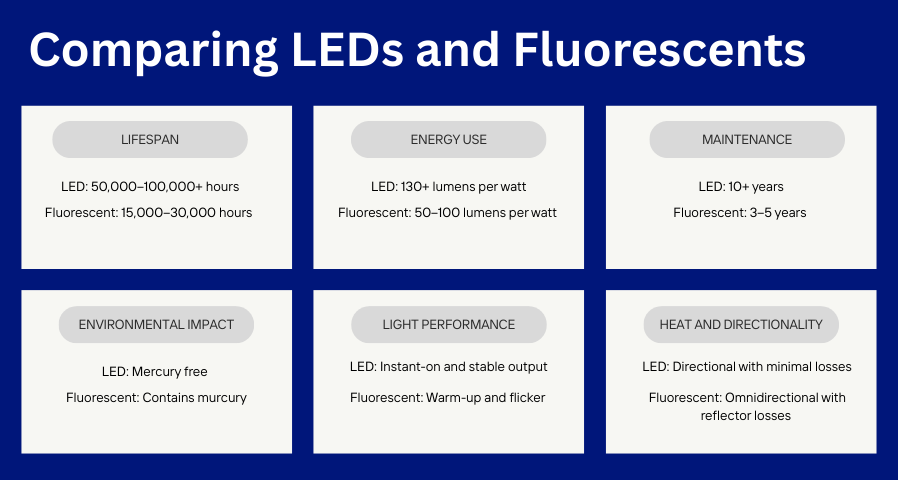

Fluorescent tubes are more efficient than incandescent lighting, but they are significantly less efficient than modern LED tubes. Traditional T8 fluorescent lamps typically produce 50–100 lumens per watt, while comparable LED tubes often exceed 130 lumens per watt. In practical terms, this means an LED tube can deliver the same or greater light output using 30–40 percent less energy.

Another important distinction is how the light is delivered. Fluorescent tubes emit light in all directions, requiring reflectors inside the fixture to redirect illumination downward. This results in optical losses and reduced system efficiency. LED tubes are inherently directional, sending most of their light exactly where it is needed and minimizing wasted lumens.

Because lighting can account for a large share of a commercial building’s electricity use, these efficiency gains translate directly into lower utility bills and reduced demand charges.

Lifespan is one of the most dramatic differences between fluorescent tubes and LEDs. A typical linear fluorescent tube lasts between 15,000 and 30,000 hours under ideal conditions, with light output declining steadily as the lamp ages. Frequent switching, cold environments, and ballast issues can shorten that lifespan even further.

LED tubes commonly operate for 50,000 to 100,000 hours before reaching end of life. They also maintain a much higher percentage of their initial light output over time. Since LEDs are solid-state devices with no fragile filaments or gas chambers, they are far more resistant to vibration, temperature swings, and on-off cycling.

Reduced replacement frequency means lower labor costs, fewer disruptions, and less risk in high-bay or hard-to-reach installations such as warehouses, gymnasiums, and manufacturing facilities.

LED technology offers superior control over color temperature and color rendering. High-quality LED tubes are available across a wide range of correlated color temperatures and typically achieve higher CRI values than fluorescent lamps. This results in more accurate color appearance, improved visual comfort, and better task visibility.

Fluorescent tubes, by contrast, rely on limited phosphor blends and often produce a narrower spectral distribution. As they age, they may flicker, hum, or shift in color, which can contribute to eye strain, headaches, and reduced visual performance.

LEDs also provide instant full brightness, even in cold environments. Fluorescent tubes may experience delayed start, reduced output, or flickering in low temperatures, making them less suitable for unconditioned spaces and outdoor applications.

Make the Right Upgrade Decision

Not all fluorescent-to-LED conversions are the same. Our free eBook, Replacing Fluorescent Lamps with LED Fixtures or Linear LED Tubes, breaks down when to retrofit, when to replace fixtures, and how to avoid common pitfalls.

Have questions after reading? Schedule a call with our experts to review your spaces and determine the best LED solution.

Every fluorescent tube contains mercury, a hazardous material that requires specialized recycling and careful handling. Breakage can release mercury vapor, and improper disposal presents environmental and regulatory concerns for facility owners.

LED tubes contain no mercury and produce no ultraviolet radiation. Their lower energy consumption also contributes to reduced greenhouse gas emissions from power generation. From both a safety and sustainability standpoint, LEDs offer a clear advantage.

Many LED tubes are designed as direct replacements for fluorescent lamps, either operating with existing electronic ballasts or bypassing the ballast altogether. This allows facilities to upgrade without replacing entire fixtures, reducing installation time and capital costs while still capturing most of the efficiency and maintenance benefits.

Are LED tubes brighter than fluorescent tubes?

Brightness depends on lumens, not wattage or technology alone. However, LED tubes typically deliver higher lumens per watt, allowing them to provide equal or greater brightness while using less power.

Can LED tubes work in existing fluorescent fixtures?

Many LED tubes are designed for direct installation in fluorescent fixtures. Some operate with the existing ballast, while others require the ballast to be bypassed. The appropriate option depends on the specific product and application.

Why do fluorescent tubes flicker as they age?

Flickering is often caused by degrading phosphors, aging electrodes, or failing ballasts. As voltage requirements increase with age, the system becomes less stable, resulting in visible fluctuations.

Do LED tubes contain hazardous materials?

No. Unlike fluorescent tubes, LED tubes do not contain mercury and are easier to handle and recycle at end of life.

How do cold temperatures affect performance?

LED tubes perform well in cold environments and start instantly. Fluorescent tubes can experience slow start, reduced output, and flickering in low temperatures.

Is the higher upfront cost of LEDs worth it?

Although LED tubes typically cost more initially, their lower energy use, longer lifespan, and reduced maintenance requirements result in a significantly lower total cost of ownership over time.

Linear fluorescent tubes played a critical role in advancing commercial lighting efficiency, but their limitations are increasingly evident in today’s performance-driven, sustainability-focused facilities. LED tube technology surpasses fluorescent lighting in energy efficiency, lifespan, light quality, safety, and environmental impact.

For organizations looking to reduce operating costs, improve visual environments, and future-proof their buildings, the transition from fluorescent tubes to LED represents a practical and financially sound investment. Action Services Group provides expert lighting services for upgrading and retrofitting LED lighting throughout your facility. To speak with our specialists, call 610-558-9773, email [email protected], or schedule a consultation that fits your needs.